ref.: CF200124

MANZONI SERIANA

Machine sold totally overhauled;

Bag length (mm): 200 – 650;Bag width (mm): 100 – 3200 (+ gusset);

Max reel width (mm): 1000;

Max reel diam. (mm): 1000;

Materials: PAPER (from 30 to 120 gr);

With in line MANZONI STE FLEXO 4 colors;

Possible to buy the machine with or without the soundproofing cabin (depending on customer requirements);

Electricity: 4,5 kw, 380 V

Maximum speed 600 pcs/min

|

...................................................................................................................................................................................................

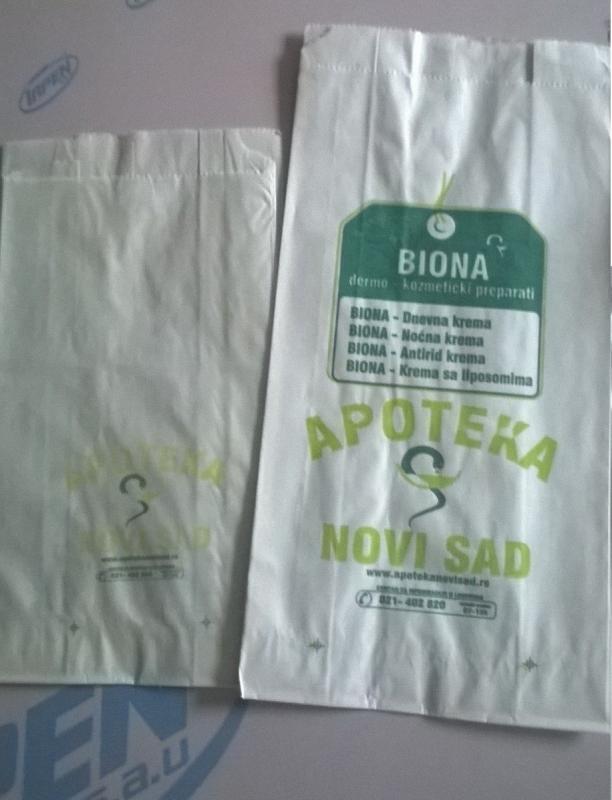

ref:120416

HONSEL PHOENIX P26

Machine for flat and satchel paper bags for bakery, fast food and candy stores, overhauled in 2011 and 2015..

Machine inline, in production,Reason for sale: factory closing..

Manufacturer: Honsel & CO - Made in Germany

Model: PHOENIX 26Printer: Honsel two-color (flexo) - anolox 100 lpi

Max. print width: 700 mm

Bag length: 120-480 mm

Bag width: 60-260 mm

Speed: 300/600 bags per minute

Motor: SIEMENS 5 kw

Additional tools:

10 forming plates widths for the bag width: 85; 100; 105; 130; 140; 145; 170; 190; 230 mm

Printing Cylinders: 2x220; 2x240; 3x270; 2x320; 1x360; 2x440 mm

length Gears bags: 2x220; 2X240; 2x270; 2X320; 2x360; 2x440 mm

Size range of manufactured bags

Width -- 80-260mm

Length -- 130-470mm

Printer width -- 700mm

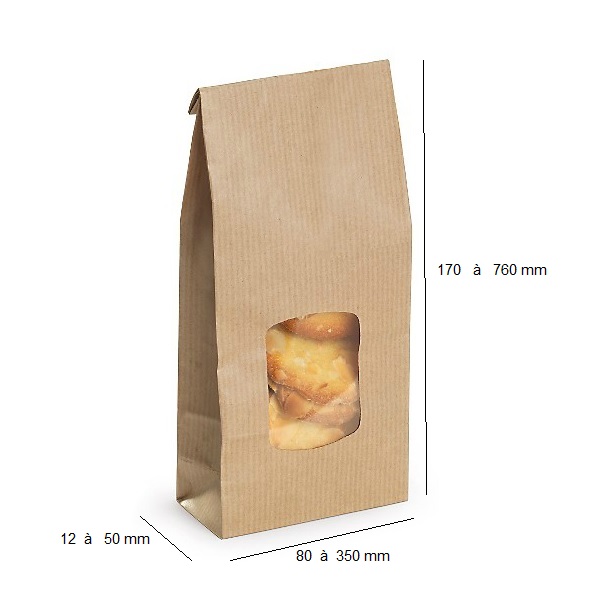

ref170316

SOMTAS : block bottom paper bag machine

BAG MASTER - WITH 4 COLOUR INLINE PRINTER

Produces flat & satchel bags with and without windows

7 servo motors

PLC controlled

Touch screen

Electronic tension control

Hydraulic lift unwind

Roll diameter: 1250mm

Maximum paper width: 900mm

Slitting facility

Film unwind

Hot melt gluing

4 colour inline flexo printer

Inter colour drying

Perforation

Cold glue station for length gluing

Pneumatic delivery station

Cutting length range: 200-780mm Bag length range: 170-760mm

Bag width range: 80-350mm

Gusset depth range: 12-50mm

Upto 500 bags/min speed, (depending on size, paper quality etc)

COLOURS: 4

YEAR: 2012

Production de sacs ou sachets avec ou sans fenetres , le systeme est equipe d'un imprimeur à 4 couleurs; 7 moteurs assistés par ordinateur à Ecran tactile. Controle de la tension se fait automatiquement en foction de la qualité du papier, enroulement -déroulement du rouleau en papier par systeme hydraulique- diametre maximale de rouleau du papier est 1200mm, Largeur maximale du papier 900mm; simple d'entretien , equipée d'un réservoir de colle et d' un système de collage automatique qui s'adapte avec le type des sacs à produire; un système peumatique est engagé pour alimenter tous verrains en service.

Longueur de coupe varie de 200 à 780mm

laissant les sacs à une longueur 170 - 760mm / largeur des Sacs 80 - 350mm

base de sacs large de 12 à 50 mm

Production peut atteindre 500 Sacs/mn selon la qualité du papier

4 couleurs

Une machine de 2012.

Baguette 10 + 6 x 38 |

Baguette 10 + 6 x 48 |

Pain 12 + 4 x 38 |

Pain 12 + 4 x 48 |

Sandwich 12 + 4 x 34 |

Tourte 27 + 8 x 34 |

réf: 070715

W&H - block bottom paper bag machine

bag width : 75-190 mm

tube cut off length : 180-470 mm

gusset bottom size 42_110 mm

flexo print unit : no

photocell control system

2 ply

TYPE: TRIUMPH 2

W&H machine à sacs en papier(2Plies) à base fermée

Type : TRIUMPH 2

Largeur de sacs 75 à 190mm

Longueur de coupe de tube 180 à 470mm

Base de sac 42 - 110mm

Pas d'imprimeur

systeme controlé par photocellule

ref:cf030715 /55218

BRAND/O.E.M.: W&H

MACHINERY: block bottom paper bag machine

TYPE: TRIUMPH 2

- With double unwind stand

- Maximum web width: 640mm

- Bag width: 75mm-190mm

- Cut of length: 180 mm-460mm

- Bottom width: 42 mm-110mm

- Mechanical speed: 200bags/min

- Printing station inline 3 colour, 650mm width

- Transversal gluing unit for 2 ply bags

- New photocell mechanical for cut in register, new electrical cabinet, new raster shafts

- Plates: 80, 100, 115, 120, 140, 150, 160

- 2 ply bags: paper + PE/PP or foil

- fully renovated 2013

YEAR: 1964

ref:cf300615

MACHINERY: block bottom paper bag machine;

Brand : NEWLONG

TYPE: 118T

2 ply. With 4 col. in-line flexographic printer. Max working width: 910 mm. Max unwind dia.: 1200 mm. Bag widths: 150-280 mm. Cut off lengths: 350-640 mm. Max mech. speed: approx. 200 bags/min. Tube widths: 150-280 mm. Tube lengths: 350-600 mm. Bottom width: 60-160 mm. Finished bag lengths: 280-530 mm. Forming plates: 220, 240 and 260mm. Gears: 370, 400, 440, 520, 620mm. Print cylinders: no. 4 x (350, 380, 420, 500, 520, 600mm ) and no. 2 x 620mm. With no. 4 anilox rolls and no. 2 ceramic rolls. Motor power: 5,5 Kw. Machine net weight: approx. 8.8 tons.

YEAR: 1984

Click here to enlarge

Click here

ref:cf250615

Block bottom paper bag machine

BRAND: F&K /TYPE: COMBI 0

for 1 ply SOS paper bags. With 4 color in-line W+H type QMS 992 flexo approx 1975 with 2 doctor blades + 4x120 anilox rolls. Bag widths: 50-120 mm. Cutting lenghts: 120-360 mm. Bottom widths: 25-75 mm. Max speed: 275 bags/min. With fully automatic NOVATECH (nowadays Holweg) packing unit for boxing the bags for bag widths from 90 to 120 mm and bag lengths from 250 to 290 mm and it can operate at the max bag production speed. Max paper web width: 400 mm. Max paper weight: 70-90 grs papers. Max reel dia.: 1200 mm. Core dia.: 70 mm. Max reel width: 400 mm. Equipped with: photocell for pre-printed reels, servo control system, slitting unit with extraction system (suction), hot-melt unit for longitudinal seam, servo drive register control (with spare motor), web cutting device for bottoms. With optical 100% monitoring bottom quality control unit. Parts: sizing sheet: 105 mm. Impression cylinders: 4x310 mm and 4 x 320 mm. Gears: 31-32.

YEAR: 2003

Polyethylen bottle recycling plants : Recyclage de bouteilles en PE

documents & details

Plant for/ligne pour 500kg/h(clic & upload doc)

plant for/ligne pour 1000kg/h(clic on)