Intes : Polymerisers (FINISHING)

capacity 80m/100 m

WIDTH: mm. 3200

POWER SUPPLY: GAS

CAPACITY: 80

Reggiani : Rotary screen printing machines

TYPE: UNICA 320/9/9

- with introdution

- with wefstraightener MAHLO

- Length printing-plane 7m.

WIDTH: mm. 3400

WORKING WIDTH: mm. 3200

COLOURS: 9

YEAR: 1997

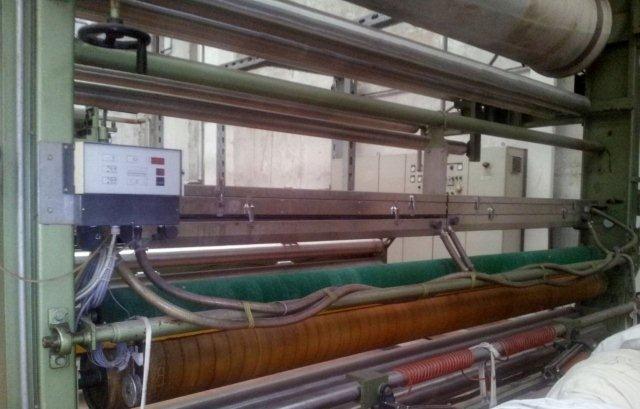

Artos : Tentering and stentering machines (FINISHING)

- with MAHLO straightening machine

- foulard KUSTERS

- coating 2000 mm

- BABCOCK pre-dryer 4 long fields 3000 mm

WIDTH: mm. 3200

POWER SUPPLY: GAS

COMPARTMENTS: 4

Production line for pre-treatment and finishing of textile for digital print

The machine can be used for:

Pretreatment of textile for digital print with maximum width up to 220 cm

Additional fixation of the inks after printing

Different finishing treatment for: water-repellency; non-flammability; treatment to make hard or soft touch of the textile and all other treatments that require soaking and squeezing of foulard and subsequent drying or fixation

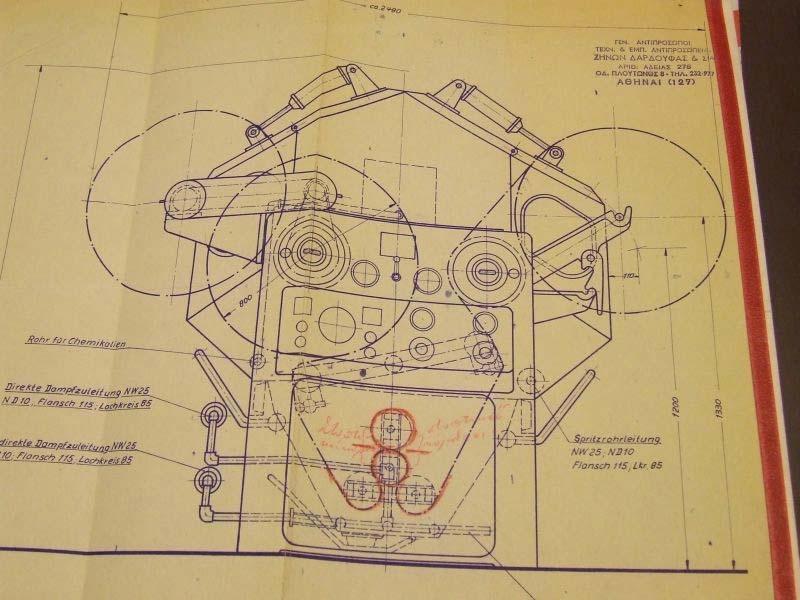

The machine is made of the following main components:

Foulard: working width of the foulard is 220 cm. It has a bathtub for soaking with capacity 40 lt. The element is equipped with two squeezing rollers, rubber covered with diameters 200 and 160 mm. IMG010; IMG012

Machine entry: The machine entry is composed of two separate swing arms with length 1300 mm. Each arm is with independent control and photocell, so that it follows the respective edge of the textile and moves as needed for even sticking of the needles into the textile. IMG002, IMG007, IMG008, IMG013

3. Driving part - The starting of the machine is made via three motors with invert control. The motors for starting the foulard, the chain and the outgoing winder. The three motors are synchronized but there is option for additional control over the speed of every unit, so that to have different crimp and the fabric to stand in weft. IMG009

The movement of the textile through the machine is made via a chain with needle plates. This movement system doesn’t allow shrinkage of the fabric width at temperature treatments. IMG001

Maximum speed is 6.5m/min.

4. Heating part - The different temperature treatments of the textile are made via infra-red heaters with total power 100kW. The temperature control is carried out by infra-red sensors and electronic control elements. This system allows to set the needed temperature for the respective treatment, as the temperature could be set from the level of the surrounding temperature up to 250 C IMG011; IMG004

The main advantage of the infra-red heating is that reaching the working temperature takes less than a minute and when working on short production runs, the losses are minimum.

The length of the heating part is 7.60 m and this allows even at maximum speed of 6.5m/min the heat exposure of the textile to be more than a minute. This time is enough for thermo-fixation of the fabric or condensation of the chemicals.

5. Outbound part - When printing with digital printers, it’s necessary to-be-printed fabric to be with cut edges. In order the textile not to unraveled when cut in edges, the cutting has to be made with high-temperature cutter. For this purpose, the machine is equipped with ultra-sound cutters IMG 003, IMG006, IMG007

The rolling of the fabric at the end is done via a rolling mechanism .

The machine is equipped with three vapor catchers. IMG014, IMG015, IMG016

In conclusion, the machine is suitable for treatment of short, as well as long production runs due to its relatively high maximum speed (appr. 400 m/hour)

Dimensions: L 11.20m, W 2.80m, H 3.00m.

High pressure MCS jigger type COMBY

JIGGER of 3400 mm working width. Composed by:

Jigger of 3600 mm cylinder width. Dyameter 1100 mm.

Hydraulic driving, loading and unloading drived by hydraulic reducer head. High pressure autoclave displaced through rails. Closure.

Heat exchanger, filter.

Adding tank, injection - circulation pump. Termoelettronica CT400 programmer.

Year 1995.

1 Kuesters foulard 222.53, ww. 3200 mm width of cylinders is 3400 mm, 2 cylinders (one "S", one polyurethan)

1 Kuesters foulard 222.17, ww. 3200 mm width of cylinder is 3400 mm, 2 cylinders "S"-type

REF:20623 KUSTERS CALENDER - WOVEN, WW 3200 MM, YEAR 1981

KUSTERS CALENDER TYPE 212.50-3200, WORKING WIDTH 3200 MM, YEAR 1981

2 BOWLS CONFIGURATION:

- TOP BOWL CHROMED STEAM HEATED

- BOTTOM BOWL S- ROLL WITH INNER PRESSURE

ENTRY WITH METAL D

EXIT WITH A-FRAME BATCHER

PRESSURE 50 TN

1 Babcock washing / bleaching range, ww. 3400 mm, y

Babcock single stage washing / bleaching range, ww. 3400 mm, yoc 1997 - for fabrics

- pre-tension entry frame

- 1st washing tank (single passage), 18 meter fabric content, compensator

- 2nd washing tank (single passage), 18 meter fabric content, 2 bowls squeeze padder

- 3rd tank saturator (single passage), 90 meter fabric content, roller bed steamer (average fabric content 2500 meter), exit from steamer with entry frame

- 4th washing tank (single passage), fabric content 18 meter

- 5th washing tank (double passage), fabric content 30 meter, 2 bowl squeeze padder

- 6th washing tank (double passage), fabric contents 30 meter, 2 bowl squeeze padder

- 7th washing tank (single passage), fabric contents 18 meter, final 2 bowl squeeze padder

- take-off by contact batcher onto A-frames

Siemens control system (AC inverters). Cpl. with chemical dosing station and filtering system with hot water heat exchanger

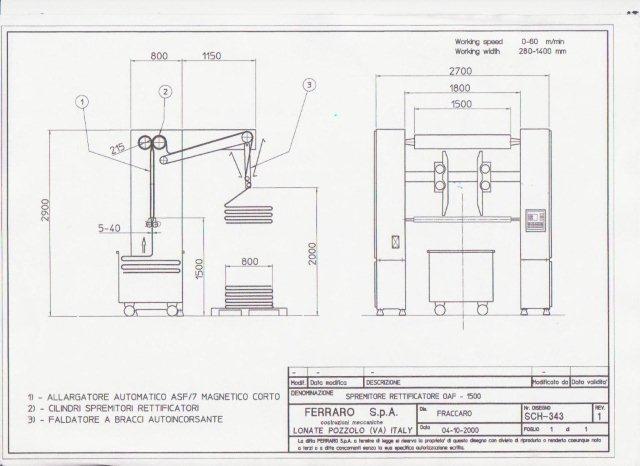

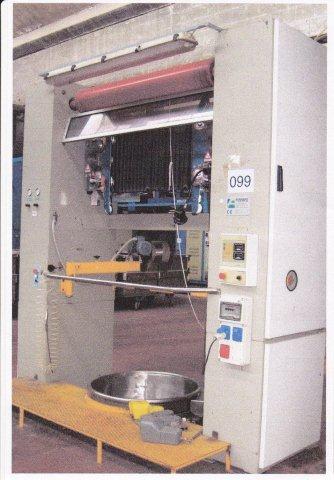

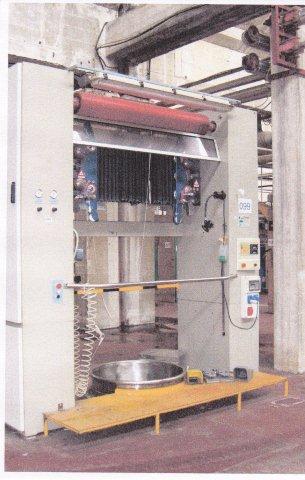

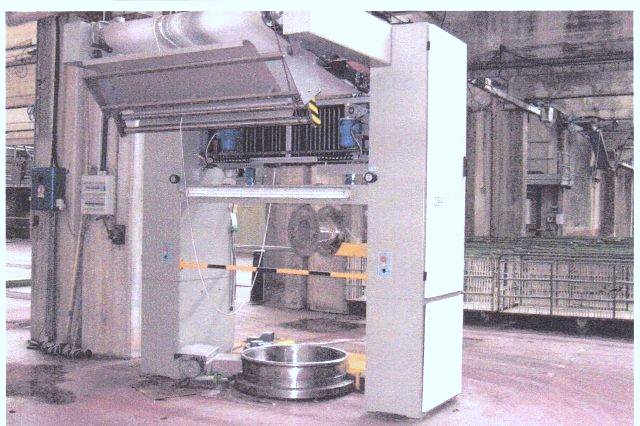

FERRARO ROPE OPENER Type: OAF

"CIBITEX" Sanfor yoc 1994.- width. 3600.-mm; ww 3400mm.

KUSTERS ARTOS THERMOSOL DYEING RANGES, WW 1800 MM

KUSTERS ARTOS THERMOSOL, WORKING WIDTH 1.800 MM, YEAR 1980 / 2005

COMPLETE WITH:

- NON STOP ENTRANCE WITH J-SCRAY

- KUSTERS DYEING PADDER TYPE 222.11-1800

- TWO GAS HEATED INFRARED PREDRYERS

- STEAM HEATED DRUM DRYER WITH 12 DRUMS

- HOT FLOW, STEAM HEATED

- NON STOP EXIT WITH J-SCRAY, MERROW SEWING MACHINE AND A-FRAME BATCHER

BRAND NEW ELECTRICAL PANEL INSTALLED IN 2005, WITH KEB INVERTERS

REF MU 120316

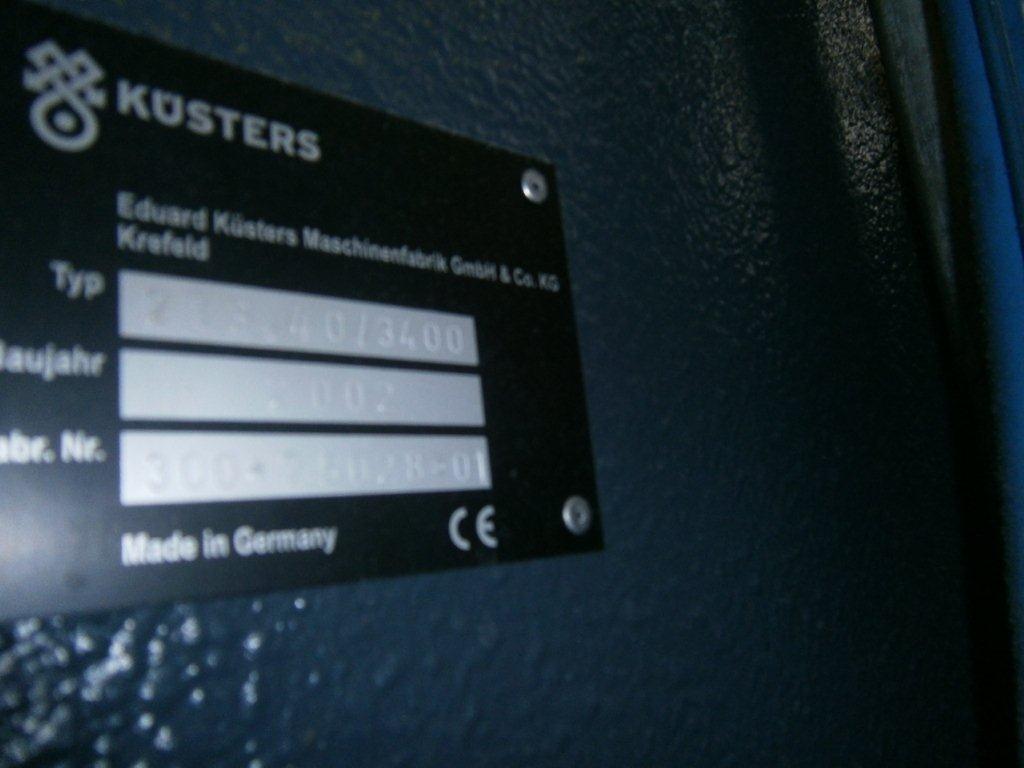

KÛSTERS GOFRER CALENDER

The entrance to the machine :

Castle complete with compensator - sewing Merrow - metal detector (search for metals) - search seams –

CALENDER GOFFRARE "KUSTERS" type 213.40 .- year of construction 2002.-

in height table mm. 3600.- useful work mm. 3400.- heating diathermic oil.-

Upper Cylinder in policotone about mm. 640.- diam.- central Cylinder - spindle steel about mm. 160.-

diam. to receive shirt of embossing from mm. 220 About diam.- Cylinder S-ROLL with diam. approximately

mm. 500.- CYLINDER FLOATING KUSTERS decline controlled with cylindrical sleeve IN FLEXROLL.-

In addition to the engraved cylinder currently mounted on the machine there are two other cylinders one with

diam. mm. 225.- ready for engraving - the other with diam. mm.220 chrome and corrected.- Device (photo n° 23

yellow and black) for the exchange kidnapped the engraved cylinders.-

N° 02 cooling rollers diam. mm. 180.- in stainless steel. Complete with valves.- UNWINDER FOR TRANSFER PAPER

rolls up to mm. 250 Diam. BALE WRAPPER FOR TRANSFER PAPER rolls up to mm. 250.- diam.- Heat Exchanger

(diathermic oil/water) for the rapid cooling of the cylinder.Exit : WINDER FOR BIG ROLL "Salvadè '" two-position

completeWidening slats - Automatic automatic shift for drawing-- braking rollerdsPneumatic for adjusting the hardness of the roto

réf: CR290216-2

PADDER KUSTERS dyeing cold (Cold Pad - batch) - type 222.11 / 1800 –

h. pl. mm. 2000 -

Imbarraggio incoming brake torque and guide tissue ERARDTH + LEIMER KF 2020

n. 2 cylinders floating in soft rubber (hardness 70 ° Shore A)

linear pressure 50 N / mm.

Overall pressure 120 KN

with stainless steel basin with running 4-cylinder diving hard rubber

jacket for steam heating

pneumatic device for lifting and lowering of the tank in order to facilitate the cleaning and the

drawing- level probe inside the tank connected to the metering pump

automatic device for quick cleaning by washing forced pan and the cylinder with a series of

sheet metal spraying arranged on all cylinders and inside the pan dye - PLC controlled

1 cylinder curved spreader installed before the point of squeezing

complete command set for a speed 'maximum of 80 mt / min.- AC motor KW 7.5 SIEMENS

high performanceframework electro-hydraulic control unit for the exercise of pressure, with

ratio controller and separate adjustment of pressure pins

1 output with arm winder BASTIAN hydraulically operated - provided with diffuse sensor to

avoid contact dyed - arm hose reel - with hydraulic power unit for axial control of carrellone

Electrical power Inverter for motor control

Machine composed of kitchen colors so 'made:

No. 01 Dosing pump SE.RA 2-stage (dose ratio 1: 4 color / alkali)

No. 01 Color kitchen equipped with:

n. 02 barrels of stainless steel with its attacks on pump

Machine totally overhauled and running with an electric engine C / a + Inverter NEW

Imbarraggio incoming brake torque and guide tissue ERARDTH + LEIMER KF 2020

n. 2 cylinders floating in soft rubber (hardness 70 ° Shore A)

linear pressure 50 N / mm.

Overall pressure 120 KN

with stainless steel basin with running 4-cylinder diving hard rubber

jacket for steam heating

pneumatic device for lifting and lowering of the tank in order to facilitate the cleaning and the

drawing- level probe inside the tank connected to the metering pump

automatic device for quick cleaning by washing forced pan and the cylinder with a series of

sheet metal spraying arranged on all cylinders and inside the pan dye - PLC controlled

1 cylinder curved spreader installed before the point of squeezing

complete command set for a speed 'maximum of 80 mt / min.- AC motor KW 7.5 SIEMENS

high performanceframework electro-hydraulic control unit for the exercise of pressure, with

ratio controller and separate adjustment of pressure pins

1 output with arm winder BASTIAN hydraulically operated - provided with diffuse sensor to

avoid contact dyed - arm hose reel - with hydraulic power unit for axial control of carrellone

Electrical power Inverter for motor control

Machine composed of kitchen colors so 'made:

No. 01 Dosing pump SE.RA 2-stage (dose ratio 1: 4 color / alkali)

No. 01 Color kitchen equipped with:

n. 02 barrels of stainless steel with its attacks on pump

Machine totally overhauled and running with an electric engine C / a + Inverter NEW

réf CR290216-1

PADDER "BETA" COMPRESSION type FMC / 3 - n ° 03 CYLINDER - STRUCTURE WITH STEEL INOX.-TABLE HEIGHT in mm. 3400.-

USEFUL mm. 3200.- with the following provision:

1. -> Rubber - diam.mm.380

2. -> Steel - diam.mm.180

3. -> Rubber - diam.mm.380

Stainless steel tank "304 The" double body suitable for double impregnation lifted pneumatically for easier threading.

-> Device division bathroom during squeezing.-

-> Pressure max.kg.26.000

-> entry with brake adgjustable.-

-> compressor "ATLAS-COPCO" built and the reservoir to maintain a constant pressure and the resulting uniformity squeezing.-.-

-> exit with restrictor-dancer 2-cylinder stationary and oscillating cylinder 1 connected to the potentiometer for synchronization controlled pneumatic.-

NEW MACHINE - NEVER START INITIATE AT TO WORK

1. -> Rubber - diam.mm.380

2. -> Steel - diam.mm.180

3. -> Rubber - diam.mm.380

Stainless steel tank "304 The" double body suitable for double impregnation lifted pneumatically for easier threading.

-> Device division bathroom during squeezing.-

-> Pressure max.kg.26.000

-> entry with brake adgjustable.-

-> compressor "ATLAS-COPCO" built and the reservoir to maintain a constant pressure and the resulting uniformity squeezing.-.-

-> exit with restrictor-dancer 2-cylinder stationary and oscillating cylinder 1 connected to the potentiometer for synchronization controlled pneumatic.-

NEW MACHINE - NEVER START INITIATE AT TO WORK

réf: CR 290216-1

1 Machine Jigger Kusters - type 268.17 JUMBO-year construction 1997.-

suitable for wash / bleach / dye fabric wide

width mm. 3400.- working width mm. 3200.-

diam.roll charge mm.1300

Group command with the new system KUSTERS controlled by Inverter

speed from 15 to 150 m / min

hot tub with direct steam and indirect

opening and closing the hood with electrical system

hood with heating coil (drip)

content bathtub dyeing min. lt.450 - max lt. 2,000

Device for oscillation at the cycle end in order to avoid accumulation of bathroom

down the roll jeopardizing the quality 'of dyeing drying step

Group suction pump and circulating bath dyeing patented "Kusters" connected with

N.02 pans stainless steel external

heat exchanger

machine completely overhaul

RE: 33623

KUSTERS CALENDER - WOVEN, WW 1600 MM, YEAR 1986

KUSTERS CALENDER TYPE 213.50-1600, WW 1.600 MM. YEAR 1986

COMPRISING:

- ENTRANCE WITH METAL DETECTOR AND TENSION BARS

- 3 BOWL KUSTERS CALENDER: TOP BOWL METAL - MIDDLE SWIMMIMG BOWL WITH RACOLAN SLEEVE - BOTTOM BOWL CHROMED GAS HEATED. BOTH TOP AND BOTTOM BOWLS ARE DRIVEN BY THE SAME MOTOR. PRESURE 50 TN

- EXIT WITH COOLING CYLINDER AND A-FRAME BATCHER

REF: 75623

BENNINGER BLEACHING RANGE FABRIC, WW 1600 MM

BENNINGER BLEACHING RANGE, WW 1.600 MM. YEAR 1980

COMPRISING:

- HIGH ENTRANCE WITH TENSION BARS, J-SCRAY ACCUMULATOR AND GUIDERS

- 2 BENNINGER EXTRACTA DOUBLE PASSAGE WASHING TANKS WITH INTERMEDIATE PADDERS

- STEAMER WITH TIGHT STRAND AND ROLLER BED

- 3 BENNINGER EXTRACTA DOUBLE PASSAGE WASHING TANKS WITH INTERMEDIATE PADDERS AND HIGH SQUEEZE PADDER AT THE EXIT

- EXIT WITH J SCRAY ACCUMULATOR, GUIDERS AND A-FRAME BATCHER

REF: 85623 OSTHOFF SINGEING MACHINE, WW 1.800 MM

OSTHOFF SINGEING DESIZING MACHINE, WW 1.800 MM. YEAR 1979

COMPRISING:

- HIGH ENTRANCE WITH TENSION BARS AND GUIDERS

- OSTHOFF SINGEING UNIT WITH TWO BURNERS (NEW BRICKS INSTALLED IN 2011)

- BRUSHING BOX

- STAINLESS STEEL DESIZING TANK WITH 5 PASSAGES AND HIGH SQUEEZE PADDER

- EXIT BY A-FRAME BATCHER

REF: 99623 STORK ROTARY PRINTING, WW 1800 MM

STORK ROTARY PRINTING RD IV -16/14

- 14 COLORS

- 3 CHAMBER GAS HEATING DRYER

WITH ALL ACCESSORIES, SCREEN WASHER AND RACLE WASHER

REF: 88623 KUSTERS PAD STEAM DYEING RANGE, WW 1800 MM, YEAR 1975

KUSTERS PAD STEAM, WORKING WIDTH 1.800 MM, YEAR 1975

COMPLETE WITH

- NON STOP ENTRANCE WITH J-SCRAY

- KUSTERS DYEING PADDER

- KUSTERS STEAMER

- KUSTERS WASHING RANGE WITH 7 TANKS AND INTERMEDIATE PADDERS

- STEAM HEATED DRUM DRYER WITH 14 DRUMS

- NON STOP EXIT

BRAND NEW ELECTRICAL PANEL INSTALLED IN 2005

WITH KEB INVERTERS

REF: 38623KUSTERS ARTOS THERMOSOL DYEING RANGES

KUSTERS ARTOS THERMOSOL, WORKING WIDTH 1.800 MM

COMPLETE WITH:

- NON STOP ENTRANCE WITH J-SCRAY

- KUSTERS DYEING PADDER

- TWO INFRARED PREDRYERS

- STEAM HEATED DRUM DRYER

- HOT FLOW, GAS HEATED.

- NON STOP EXIT WITH J-SCRAY AND A-FRAME BATCHER

REF: 18623 MARIO CROSTA SUEDING, WW 1800 MM

MARIO CROSTA SUEDING MACHINE, 1.800 MM WORKING WIDTH

SINGLE DRUM WITH 36 CYLINDERS

Julien Singeing machines

- width 2.200 mm

- guidance tissue

- HINERYbrushing unit

- 2 burners at both fabric sides with cooling cylinders

- including units of cleaning

- pad batch desizing composed by big tank in stainless steel

- padder and outlet by a frame

- possibility to attach 2 burners OSTHOFF

WIDTH: mm. 2200

YEAR: 1991

ref:cf161215

ref:cf110915-2

Unitex : Jigger (HT) 143°C

- working width 2000 mm

- With programmer

- Output fabric: large roll

- Supply voltage: 380 V / 50 Hz.

WIDTH: mm. 2200

MAX DIAMETER ROLLS: 1150

YEAR: 2001

ref:cf110915-1

Comet : Shearing machine

TYPE: ORION 2000

WIDTH: mm. 2400

YEAR: 1999

ref:cf110915

BRUCKNER: Tentering and stentering machine

WIDTH: mm. 1800

POWER SUPPLY: GAS

COMPARTMENTS: 9

YEAR: 1982

ref:cf210715

Biancalani: Tumbler /Finishing machines

TYPE: AIRO 1000 SPE

- One works in wet the other only dry

- year 1993 and 1995

POWER SUPPLY: STEAM

ARIOLI CONTINUOUS OPEN WIDTH WASHING LINE

AFTER PRINTING FOR FABRICS WITH 5 TANKS, WORKING WIDTH 2000MM, YEAR 1986 - HIGH ENTRANCE WITH TENSION BARS AND KUSTER GUIDER AND SPREADERS - 1ST TANK WITH 1 PERFORATED DRUM, DIAMETER 1.200 MM - INTERMEDIATE SQUEEZER WITH 2 BOWLS - 2ND TANK WITH 4 PERFORATED DRUMS, DIAMETER 450 MM - INTERMEDIATE SQUEEZER WITH 2 BOWLS - 3RD TANK FOR THE FABRIC RELAXING, WITH DOUBLE CONVEYOR IN STAINLESS STEEL (THE FABRIC RUNS IN BETWEEN THE TWO CONVEYORS) - INTERMEDIATE SQUEEZER WITH 2 BOWLS - 4TH TANK WITH 4 PERFORATED DRUMS, DIAMETER 450 MM. - INTERMEDIATE SQUEEZER WITH 2 BOWLS - 5TH TANK WITH 1 PERFORATED DRUM, DIAMETER 1.200 MM. - INTERMEDIATE SQUEEZER WITH 2 BOWLS - HEAVY SQUEEZER WITH 2 BOWLS, WITH IMPREGNATION TANK - EXIT BY PLATER - THE TANKS ARE EQUIPPED WITH SELF-CLEANING FILTER - ELECTRIC CONTROL BOARD AND CONTROL CONSOLE - DIMENSIONS OF THE LINE : LENGTH ABOUT 16.000 MM. – WIDTH ABOUT 4.500 MM THE MACHINES HAVE NO PLATES, BUT WE HAVE FOUND THE CONSTRUCTION YEAR ON THE ELECTRIC DRAWINGS

For more photos click on the text to upload file

- RUCKH dryer for knitteds, gas heated, BIANCO padder. Year 1994.

Ref:cf140515-2

Corino Machine : Rope opening

WIDTH: mm. 3600

YEAR: 1999

Ref:cf140515-1

Bianco: Rope opening

- rope opener line with cutter on wet

- Multi-purpose machine for fabrics in rope ideal for operations after washing and dyeing

Machine consisting of:

- Squeezing rope

- Scaffolding with automatic unwinder

- Basket cutter countersinks and centering cylinders with tow

- hydro extractor EVAC

- squeezing / impregnation

- Comprised of EC legislation

WIDTH: mm. 2000

YEAR: 1998

Ref:cf130515-4

Corino

Macchine : Rope opening

TYPE: EKS 2504

- rope opener EKS 2504 cutter with automatic knitting

- working width 2400 mm

- delivered lap

WIDTH: mm. 2400

YEAR: 1991

Ref:cf130515-3

Bianco:

Rope opening

WIDTH: 2400mm.

YEAR: 1997

Ref:cf130515-1

Sperotto

Rimar : Compactor

TYPE: CK-240

Composed of:

- constant hydraulic unroller

- weftstraightener Malho for knitting

- rame open for guided and vaporized with automatic entry and overeating

- compacted unit with two filters compacted on both sides of the fabric

- Automatic output with inspection and tension control

WIDTH: mm. 2400

YEAR: 1999

ref110515 2 Jaeggli-Meccanotessile - Mercerizing machine MRC12

TYPE: Jaeggli- Meccanotessile modello HL2000

- Hanks Mercerizing Machine, with moving tank

- two compartments with caustic soda and two compartments for wash water collection

- each machine produces about 100 kg / h of yarn skeins 1Kg/cad. for a total of 800Kg. per shift.

- Autoloaders

- Hydraulic system shot with variable flow control, with 4 pistons firing control with encoder

- A mixing plant for the preparation of sodium hydroxide for mercerizing in skeins, manufacturing Switzerland built by the company Merc-Control ag Kasag; model "Eco-Block", built in 1999.

- A plant for the separation of impurities present in the washing solution, such as spinning oils, wetting agents dispersed and exhausted in the bath of the lye, pectins and sugars derived from cellulose treated in mercerizing step. Manufactured by Merc-Control a.g. Kasag; model "Separator OAS", built in 1999.

WIDTH: 2000 mm

YEAR: 2000

ref 84123 BRAZZOLI JET DYEING AT

BRAZZOLI AT JET DYEING MACHINE SUITABLE FOR TOWEL

CAPACITY 400 KG

4 ROPES

ref 86023 MCS JET DYEING AT

MCS AT JET DYEING MACHINE

MODEL PANDORA PA450BT

CAPACITY 300 KG

3 ROPES

ref:46023 BRAZZOLI JET DYEING AT

BRAZZOLI AT JET DYEING MACHINE MODEL CAMELDYE

CAPACITY 600 KG

4 ROPES

ref :76023 MCS JET DYEING HT

MCS HT JET DYEING MACHINE MODEL PANDORA 600 HT. YEAR 1988

Ref:34603 BENE JET DYEING HT

BENE HT JET DYEING MACHINE, YEAR 1988

CAPACITY 450 KG

3 ROPES

BARCO SEDO PROGRAMMER

SUITABLE FOR TOWEL, NOZZLE OF 30 CM

K05 \40064

1 autoclave de Teinture sur ensouple THEN, Type HAST-130-16, année 1973

Capacité 300 kg, largeur utile 1 m 60, programmation SETEX 737

1 autoclave de Teinture sur ensouple THEN, Type HST 105-16, année 1973

Capacité 150 kg, largeur utile 1 m 60, programmation SETEX 737

1 THEN Beam Dyeing Autoclave, Type HAST-130-16, year 1973

Capacity 300 kg, working width 1 m 60, SETEX Programming Type 737

1 THEN Beam Dyeing Autoclave, Type HST 105-16, year 1973

Capacity 150 kg, working width 1 m 60, SETEX Programming Type 737

M18 \43329

1 Emballeuse de tissu ICBT, année 1995, Type EF 100, largeur 260 cm

Soudage du film plastique longitudinal et extrémité

5 tapis d'alimentation et d'évacuation, basculeur, potence murale

1 ICBT Cloth packing machine, year 1995, Type EF 100, width 260 cm

Welding of Plastic film: longitudinal and extremity

5 feeding and evacuation belts, pivoting arm, wall bracket

M19 \815855

1 Emeriseuse LAFER AQUASAND de 1997, tambour unique, à papier diamanté

Table largeur 2000 mm, largeur utile 1850 mm.

Groupe brossage modèle SPLH 1900 de 1997, Inverter, aspiration.

M20 \40899

1 tête d'enduction rotative STORK type CT 4, double tête, année 1985

largeur cylindre 1900 mm; largeur utile racle 1700 mm

Équipée pour 2 cylindres rotatifs de 640 mm de rapport et 920 mm.

Avec racle élargisseuse en sortie, racle avec lame acier dans le cylindre

+ 1 Laveuse de cadres rotatifs à 1 poste, largeur 2000 année 2003

1 STORK Rotary Coating head type CT 4, double head, year 1985

Cylinder width 1900 mm, doctor blade working width 1700 mm

Fitted for 2 rotary cylinders of 640 mm and 920 mm repeat

with expanding doctor blade at delivery.

+ 1 rotary screen washing machine, width 2000, year 2003

M23 \36589

1 enrouleur double automatique CMC de 2003, largeur utile maxi = 1,62 m

dia. maxi des bobines = 1000 mm, vitesse maxi 250 m/mn

1 CMC automatic double rolling device, year 2003, working width: 1,62 m

maximum dia. 1000 mm, maximum speed: 250 m/mn

M30 \43487

1 Machine d'impression numérique MUTOH, Type VIPER TX100 digitale

Année 2007, largeur 260cm, sublimation directe sur tissu ou papier transfert

1 MUTOH Digital printing machine, Type VIPER TX100 digital

Year 2007, width 260cm, Direct to textile and dye sublimation printer

M32 \43488

1 Calandre d'impression par transfert TRANSMATIC, Type GFO126/60, année 2008

Largeur 320 cm, chauffage électrique, diamètre de cylindre 60

1 TRANSMATIC Thermo-printing Calander, Type GFO126/60, year 2008

Width 320 cm, electric heating, cylinder diameter 60

M37 \43015

1 Laveuse au large à la continue WET-TEX, année 1998

Largeur des cylindres 340 cm, largeur utile 320 cm

Vitesse de production 30 m /min

2 compartiments principaux de lavage (compartiments de lavage intensif)

1 compartiment de rinçage ou compartiment neutralisant

1 WET-TEX Continuous washing range, year 1998

Cylinders width 340 cm, working width 320 cm

Production speed 30 m /min

2 main washing compartments (intensive washing compartments)

1 rinsing or neutralizing compartment

Between drainage facilities (mill/ aspirate)

M37 \43473

1 Ligne de Lavage composée de:

- 1 Accumulateur J-BOX

- 1 Laveuse TVE, année 2003, largeur 260 cm, largeur utile 240 cm, inox

Vitesse maxi 50m/mn, Température maxi 100 deg.

Chauffage vapeur indirecte et échangeur de chaleur

1 Washing range, consisting of:

- 1 J-BOX accumulator

- 1 TVE washing range, year 2003, width 260 cm, working width 240 cm,

Stainless steel, maximum speed 50m/mn, maximum temperature 100 deg.

indirect steam heating and heat exchanger

M46 \43330

1 ouvreuse tubulaire ICBT, année 1995, largeur 220 cm

Avec dérouleur et enrouleur

Coupe par lame scie, bras de pliage

1 ICBT slitter for tubular fabrics, year 1995, width 220 cm

With unrolling and rolling devices

Cutting by saw blade, folding arm

M51 \43046

1 Rame MONFORTS Type MONTEX 14G/K, année 1991, 7 compartiments

largeur 2600 cm (utile 240 cm), équipée maille, chaîne verticale à picots

chauffage thermo-fluide, suralimentation, entrée avec compartiment vapeur

Avec dérouleur axial double et foulard MONFORTS à 2 cylindres à l'entrée

Compartiment refroidisseur, enrouleur axial et plieur en sortie

Avec chaudière thermo-fluide EMK année 1996, type THERMIFLOW TO 2000/1500

1745 kW - 1700 litres

1 MONFORTS Stenter Type MONTEX 14G/K, year 1991, 7 chambers

Width 2600 cm (working width 240 cm), fitted for knitted fabrics, vertical pin chain

Thermo-oil heating, overfeeding, entry with steaming chamber

With double axial unrolling unit and MONFORTS 2 cylinder padder at entry

Cooling chamber, axial batcher and plaiter at delivery

With EMK Thermo-oil Boiler, year 1996, type THERMIFLOW TO 2000/1500

1745 kW - 1700 litres

M52 \43474

1 Ligne de séchage composée de

- 1 Rame à étages EFFEDUE F2 modèle TLS 2002, année 2003, 3 étages

Largeur de travail: minimum 1000 mm ; maximum 2400 mm

Chambre de sèche et/ou thermo fixation constitué de 3 compartiments

Longueur totale du four de séchage : 46 m environ, 12 brûleurs gaz naturel

- Redresseur de trame MAHLO, année 1996

- 1 Visiteuse + 2 postes d'enroulage EFFEDUE, année 2003 Type AR 2400

1 Drying range, consisting of:

- 1 EFFEDUE Tier Stenter Type F2 model TLS 2002, year 2003, 3 levels

Minimum working width 1000 mm; maximum 2400 mm

Drying and/or thermo-fixation unit composed of 3 compartments

Total length of drying oven: approx. 46 m, 12 natural gas burners

- MAHLO Weft straightener, year 1996

- 1 EFFEDUE Inspection table + 2 rolling units, year 2003 Type AR 2400

ALBRECHT mercerizer for tubular of 1200 mm width/

Mercerizadora para tubular ALBRECHT ancho 1200 mm /

Ligne de mercerisage ALBERT pour tubes 1200mm de large

ALBRECHT washing range for tubular of 1200 mm width /

Tren de lavado para tubular ALBRECHT ancho 1200 mm /

Train de lavage ALBERT pour tubes de largeur 1200mm

ref:80713

BRUCKNER ROPE WASHING AND BLEACHING RANGE , YEAR 1991

TYPE DELPHIN / D12 WITH 12 WASHING SECTIONS

COMPRISING:

- OPEN IMPREGNATION TANK

- BRUCKNER ROPE WASHING AND BLEACHING RANGE TYPE DELPHIN / D12

- EACH TANK WITH CHEMICAL DOSING AND CIRCULATION PUMPS

- TAKE OFF ON TO J BOX COMPENSATOR

BIANCO DETWISTER ROPE OPENER

COMPRISING:

- HIGH ENTRY, AUTOMATIC DETWISTER, WITH BIANCO COMPACT- C GUIDER SYSTEM

- BIANCO WATER EXTRACTION SQUEEZING PADDER

- TAKE OFF BY PLAITER

Kusters Padding mangles

TYPE: Cold Pad-batch 222.50

- In guided tissue E + L

- KUESTERS dyeing padder type 222.50

- width 2000 mm working width 1800 mm

- 2 cylinder floating

- control panel and electrical panel general

- Output to reel in big rolls BASTIAN

WIDTH: mm. 1800

YEAR: 1990

Bianco: Batch rollers

Winder for big rolls

WIDTH: mm. 2000

YEAR: 1990

STORK TRANSFER PRINTING MACHINE

MODEL TC131/2000, WORKING WIDTH 1.800 MM. YEAR 1995

DRUM DIAM. 760 MM

MAX. SPEED 20 M/MIN

MAX. TEMP. 240ºC

HEATING SYSTEM: ELECTRIC RESISTENCE ON OIL

TOTAL POWER: 70 KW

CONTACT ZONE: 300º

MACHINERY: Sanfor - Shrinking machines

TYPE: MONFORTEX SG

- type MONFORTEX SG

- width 2000 mm

- with accumulators PAGANINI 1992

Composed of:

-J-Scray

- fabric Tensioning device

- pre-Steaming and moisturizing Cylinder

- water cooled cooling cylinder

- mini Tenter for stretching

- rubber belt unit

- palmer with felt unit

- j-scray at exit

- batcher at exit

- 380v, 50hz

WIDTH: mm. 2000

YEAR: 1981

ref 030415-1

Beta FLT80 : Padding mangles

WIDTH: mm. 2000

CYLINDERS: 3

ref 030415-3

MACHINERY: Sanfor - Shrinking machines

TYPE: TOPTEX/W

- type TOPTEX/W

- width 1800 mm

- MAHLO ELOTEX

WIDTH: mm. 1800

YEAR: 1988

ref 030415-4

BRAND/O.E.M.(original equipment manufacturer): Monforts SNF54

MACHINERY: Sanfor - Shrinking machines

TYPE: TOPTEX

- working width 2000 mm rolls w. 2200 mm - machine is still running - very good technical condition

WIDTH: mm. 2200

POWER SUPPLY: STEAM

YEAR: 2000

ref 030415-5

BRAND/O.E.M.(original equipment manufacturer): Monforts SNF62

MACHINERY: Sanfor - Shrinking machines

TYPE: TOPTEX/W

- small stenter at the entry with automatic weftstraightener BIANCO

- with pr?-dryer infra-red system of the selvedges

- exit by Non-Stop CORINO

YEAR: 2000

ref 030415-6

BRAND/O.E.M.(original equipment manufacturer): Ramallumin ESC4

MACHINERY: Drum drying machines

DRUM DRYING MACHINES

- 11 cylinders width 1800 mm diameter 640 mm

- 5 cylinders width 2000 mm diameter 640 mm

CYLINDERS: 16

ref 030415-7

BRAND/O.E.M.(original equipment manufacturer): Gavazzi PIP3

MACHINERY: dispensing machine

TYPE: color 2060

ref 030415-8

MACHINERY: Foulard from laboratory

YEAR: 2003

ref 030415-9

BRAND/O.E.M.(original equipment manufacturer): Datacolor SPET5

MACHINERY: spectrophotometer

TYPE: SPECTRAFLASH 600

- with software DATAMATCH

YEAR: 2001

ref 030415-10

BRAND/O.E.M.(original equipment manufacturer): Gavazzi MSC2

TYPE: CAMPIOCOLOR 85/A

ref 030415-11

BRAND/O.E.M.(original equipment manufacturer): Gavazzi LAM4

MACHINERY: fabric inspection lamp

TYPE: PROVACOLOR

ref 030415-12

MACHINERY: Jumbo roll carriage

LEMAIRE Calender

Brand and Type : LEMAIRE

Features :

type MV-R, width 2000 mm

20 knives

1 TESTUT scale graduation 500 kgs/500 gr and plate 2000 x 1500 mm

1 heating system 1 hood with fan and chutefeed

1 Lifknet hoist 250 kgs with monorail

ref 140315

BRAND/O.E.M.(original equipment manufacturer): M.A.T

MACHINERY: Crabbing

TYPE: CONTIKRABBING

YEAR: 1991

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

réf130315

BRAND/O.E.M.(original equipment manufacturer): M.A.T

MACHINERY: Milling/fulling machines

TYPE: COMBISOFT

YEAR: 1997

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

BRAND/O.E.M.(original equipment manufacturer): M.A.T

MACHINERY: Milling/fulling machines

TYPE: COMBISOFT

YEAR: 1993

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

ref150315

BRAND/O.E.M.(original equipment manufacturer): Bastianelli

MACHINERY: Bag stitching and end-to-end sewing machines

YEAR: 1981

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

REF: 31556 BIELLA KD DECATISING- BATCH, WW 1700 MM, YEAR 1997

BIELLA KD BATCH DECATISING MODEL KD SUPREMA 95, YEAR 1997

DIAMETER 1300 MM

EXIT WITH CONVEYOR BELT, COOLING SUCTION DEVICE AND FOLDER

WITH ALMOST NEW SATIN

REF: 31555 BIELLA DECATISER- CONTINUOUS, WW 1700 MM

BIELLA SHRUNK PROCESS DECATIZER MODEL THERMO DUPLEX, YEAR 2001.

WITH BIANCO OPTICAL WEFT STRAIGHTENER YEAR 2002

INCLUDING BRUSHING

réf70315

LORIS BELLINI BEAM DYEING, YEAR 2007

2 LORIS BELLINI AUTOCLAVE FOR YARN DYEING, YEAR 2007

CAPACITY 324 CONES OF 290 MM x 210 MM EACH, APPROX. 1.100 KG MATERIAL EACH

TWO SETS OF CARRIERS EACH

COLOURS KITCHEN OF TWO TANKS EACH

THEY CAN WORK TOGETHER OR SEPARATE

HYDROESTRACTOR LORIS BELLINI, YEAR 2007

CAPACITY 24 CONES (WITH POLYESTER DRYINGS IN 3-4 MIN.), ADAPTED FOR THE DYEING SYSTEM OF THE MANUFACTURER, WITH CRANE OF GRAVITATORY INVERSION SYSTEM

réf170215

ANGLADA CONTINUOUS TUMBLER, WW 3200 MM, YEAR 1999

ANGLADA TUMBLER MODEL SIMPLEX TDR 3.2 S, YEAR 1999

WORKING WIDTH 3.200 MM

GAS HEATED

EXIT WITH CONVEYOR BELT, COOLING DEVICE AND FOLDER

réf:130215

2 Stenter Frames - Babcock made in Germany

yoc 1 x 1995, 1 x: 1997

8 chambers, oil heated, ww. 180 cm, max. width 2 meter,

working with pin chain (horizontal), Mahlo weft straightener,

padder like new,

in excellent running condition,

with weft straightener,

380 Volt, 50 Hz.

delivery immediately

both stenters are highly suitable for knit fabrics as well as woven.

réf:090215

.jpg?timestamp=1425739282853)

ARIOLI WASHING RANGE KNITS, WW 1800 MM, YEAR 1995

ARIOLI CONTINUOUS WASHING LINE AFTER PRINTING FOR FABRICS WITH 5 TANKS, WORKING WIDTH 1.800MM, YEAR 1995

- ROLLER WIDTH 2.000 MM

- WORKING WIDTH 1.800 MM

- HIGH ENTRANCE WITH TENSION BARS AND BIANCO GUIDER AND SPREADERS

- 1ST TANK WITH 1 PERFORATED DRUM, DIAMETER 1.200 MM

- INTERMEDIATE SQUEEZER WITH 2 BOWLS

- 2ND TANK WITH 4 PERFORATED DRUMS, DIAMETER 450 MM

- INTERMEDIATE SQUEEZER WITH 2 BOWLS

- 3RD TANK FOR THE FABRIC RELAXING, WITH DOUBLE CONVEYOR IN STAINLESS STEEL (THE FABRIC RUNS IN BETWEEN THE TWO CONVEYORS)

- INTERMEDIATE SQUEEZER WITH 2 BOWLS

- 4TH TANK WITH 4 PERFORATED DRUMS, DIAMETER 450 MM.

- INTERMEDIATE SQUEEZER WITH 2 BOWLS

- 5TH TANK WITH 1 PERFORATED DRUM, DIAMETER 1.200 MM.

- INTERMEDIATE SQUEEZER WITH 2 BOWLS

- HEAVY SQUEEZER WITH 2 BOWLS, WITH IMPREGNATION TANK

- EXIT BY PLATER

- THE TANKS ARE EQUIPPED WITH SELF-CLEANING FILTER

- ELECTRIC CONTROL BOARD AND CONTROL CONSOLE

- DIMENSIONS OF THE LINE : LENGTH ABOUT 16.000 MM. – WIDTH ABOUT 4.500 MM

THE MACHINES HAVE NO PLATES, BUT WE HAVE FOUND THE CONSTRUCTION YEAR ON THE ELECTRIC DRAWINGS

réf:260115

KUSTERS CALENDER - WOVEN, WW 1700 MM, YEAR 1987

KUSTERS CALENDER TYPE 212.50.1600, WORKING WIDTH 1700 MM YEAR 1987

- 2 BOWLS: TOP BOWL CHROMED OIL HEATED, BOTTOM BOWL SWIMMING BOWL WITH RACOLAN SLEEVE

- WORKING PRESSURE 50 TN

- ENTRY WITH METAL DETECTOR, SEAM DETECTOR AND OIL HEATED CILINDER FOR FABRIC PREHEATING

- COOLING CILINDERS

- EXIT CONTACT BATCHER ONTO A-FRAME.

FABRIC TENSION CONTROL SYSTEM

2 SPARE S - BOWLS

MACHINE COMPLETE AND IN PERFECT WORKING CONDITIONS

réf:mte210115

1 MCS 300 jigger,ww 3.000 mm.,Atm temp. , CT400 programmer, year 1993

Working temperature : up to 98 °C (Atmospheric not high temperature)

For dyeing ,bleaching and washing operations.

Power 15 Kw , V 380-50 Hz

Dimensions : 4.600 x 5150 (feeding fabric roll included) x 2500 mm about

réf:mte1-41114

BRAND/O.E.M.(original equipment manufacturer): RAMISCH

MACHINERY: Calenders

CALENDERS

- 2 cylinders : one in racolan and one in steel

- 1 spare cilynder

- width 2000 mm

- pressure 40ton

- 1 roller unroller Ramish in

- 1 roller unroller Ramish in out

WIDTH: mm. 2000

CYLINDERS: 2

YEAR: 1971

réf170115

Cone dyeing

2 Jasper 1250 cone dyeing machine, HT , 4,5 bar, capacity 330 kgs. Barco Sedomat 3500 programmer, year 2002

1 Jasper 850 cone dyeing machine, HT , 4,5 bar , capacity 140 kgs. ,Barco Sedomat 3500 programmer, year 1998

1 Jasper 600 cone dyeing machine , HT , 4,5 bar ,capacity 80 kgs, Barco Sedomat 3500 programmer,year 998

2 Jasper tandem dryers, year 1998

1 Jasper loader/unloader,year 1998

Fabric dyeing finishing

4 Scholl Rapidstar RMC fabric dyeing machines, HT , 4,5 bar , Barco Sedomat 5000 programmer , year 2002

2 machs capacity 200 kgs. -1 rope

1 mach. capacity 400 kgs. -2 ropes

1 mach. capacity 800 kgs. -4 ropes

1 Surfer dyeing machine, Atm temp., capacity 400 kg., Sedomat PC3100 programmer, year 1994

2 Thies Ring soft dyeing machine, Atm temp., TC10 programmer

1 mach. capacity 200 kgs. -2 ropes year 1986

1 mach. capacity 400 kgs. -4 ropes year 1989

1 Krantz hydro-extractor ,capacity 200 kgs., year 1986

1 MCS 300 jigger,ww 3.000 mm.,Atm temp. , CT400 programmer, year 1993

1 Bianco spreader,year 1989

1 Lawer dosing system ,20 tanks with capacity 200-1.200 liters , 2 outside tanks 1.500 liters, year 2002

1 Crosta shearing machine , ww 1.800 mm., year 1975

1 line , ww 2.450 mm., consisting of : foulard , Krantz tumbler, Mahlo weft-streightner , Babcock stenter ,year 1999

réf mte2-51214

Krantz stenter machine as below:

Year 2001

Model : K30

Working width : 2400mm

8chambers, oil heating type, vertycal, pin,

Pinning device: Tandermatic - USA

Photocell: E&L

2Padders.

Central device.

Weft-straighterner - Mahlo.

Controller : PLC

Condition: Stop very good condition - can inspect running condition.

réf mte1-51214

Monforts 7 chamber oil heated Stenter Machine - 2003 model for sale

Monforst stenter picture & under detail.

> Year: 2003

> Model: Montex5000

> Working width: 2400mm

> 7chambers, oil heating

> Pin, horizotal, centraling device,

> Pinning device: Tandermatic- USA

> Humidity system .

> Photo cell: E&L

> Padder: 2rollers.

> Westraighterner- Mahlo

> Controller system : PLC & inverter.

> Condition: Stop but you can inspect running condition without fabric.

réf:mte2-41114

BRAND/O.E.M.(original equipment manufacturer): Anzini

MACHINERY: Calenders

- width 2800 mm working width 2600 mm

- upper cylinder in woolpaper large diameter

- central cylinder in chromed steel

- lower cylinder in cotton large diameter

- completely revised year 2000

- total revamp of the electrical panel year 2000

- a bundle of resistors new parts

WIDTH: mm. 1800

POWER SUPPLY: ELECTRICITY

CYLINDERS: 3

YEAR: 1988

......................................................................................................................................................

réf:mte3-41114

BRAND/O.E.M.(original equipment manufacturer): Anzini

MACHINERY: Calenders

- 3-roll calender silk fabric chintz

- width 1800 mm working width 1700 mm

- upper cylinder in woolpaper large diameter

- central cylinder made of special steel microincision chintz

- lower cylinder in cotton

- machine completely overhauled year 2000

- correction of the three-cylinder year 2000

- complete revision of the electric panel year 2000

WIDTH: mm. 2800

POWER SUPPLY: ELECTRICITY

CYLINDERS: 3

YEAR: 1986

REF: 31708 BRUCKNER ROPE WASHING, YEAR 1991

BRUCKNER ROPE WASHING AND BLEACHING RANGE TYPE DELPHIN / D12 WITH 12 WASHING SECTIONS

COMPRISING:

- OPEN IMPREGNATION TANK

- BRUCKNER ROPE WASHING AND BLEACHING RANGE TYPE DELPHIN / D12

- EACH TANK WITH CHEMICAL DOSING AND CIRCULATION PUMPS

- TAKE OFF ON TO J BOX COMPENSATOR

BIANCO DETWISTER ROPE OPENER

COMPRISING:

- HIGH ENTRY, AUTOMATIC DETWISTER, WITH BIANCO COMPACT- C GUIDER SYSTEM

- BIANCO WATER EXTRACTION SQUEEZING PADDER

- TAKE OFF BY PLAITER

REF: 31702 BRUCKNER STENTER KNITS, YEAR 1991, WW 2000 MM, YEAR 1994

BRÜCKNER STENTER FOR KNITTED FABRICS, WW 2000 MM. YEAR 1994 / 2001

COMPRISING:

- HIGH ENTRY WITH BIANCO GUIDER AND SCROLL ROLLERS

- KUSTERS 2 BOWL PADDER WITH ONE S-ROLL

- MAHLO ORTHOMAT WEFT STRAIGHTENER, YEAR 2001

- BRÜCKNER STENTER FOR KNITTED FABRICS WW 2000 MM, OIL HEATED, 6 CHAMBERS, VERTICAL PIN CHAIN, GUM APPLICATION & TRIMMING SYSTEM, LONG ENTRY, OVERFEED SYSTEM, PRE STEAMING UNIT

- EXIT BY TESSIONLESS BATCHER ON A-FRAME AND PLAITER

MACHINE FULLY UPGRADED IN THE YEAR 2001, INSTALLING NEW WEFT STRAIGNER AND THE TENSIONLESS BATCHER

REF: 9639 BRUCKNER ROPE WASHING, YEAR 2000, WW 1800 MM

BRUCKNER OPEN WIDTH AND ROPE WASHING & BLEACHING RANGE WITH ROPE OPENER, PADDER AND TENSIONLESS DRYER, WORKING WIDTH 1.800 MM, YEAR 2000

SUITABLE FOR TERRY TOWEL AND KNITTED FABRICS COMPRISING OF:

- SECTION 1: WASHING/BLEACHING

BRUCKNER OPEN WIDTH WASHING RANGE TYPE SCOUT TR3 WITH 3 OPEN WIDTH PERFORATED DRUM WASHING UNITS, EACH WITH 2 BOWL SQUEEZE PADDERS 1.800 MM WORKING WIDTH, EACH TANK WITH CHEMICAL DOSING AND CIRCULATION PUMPS, ENTRANCE WITH HIGH ENTRY WITH BIANCO COMPACT- C GUIDER SYSTEM, TAKE OFF ON TO J BOX COMPENSATOR

BRUCKNER ROPE WASHING RANGE TYPE DELPHIN II /D16 WITH 16 WASHING SECTIONS

EACH TANK WITH CHEMICAL DOSING AND CIRCULATION PUMPS, TAKE OFF ON TO J BOX COMPENSATOR

- SECTION 2: OPENING THE FABRIC

BIANCO DETWISTER ROPE OPENER

HIGH ENTRY WITH BIANCO COMPACT- C GUIDER SYSTEM

KUSTERS WATER EXTRACTION SQUEEZING PADDER WITH ONE S ROLL

TAKE OFF BY PLAITER

- SECTION 3: DRYING

BRUCKNER TENSIONLESS CONVEYOR DRYER 3 PASS AND 3 SECTIONS

THERMAL OIL HEATING, ENTRANCE WITH PRE TENSION ENTRY WITH BIANCO DOGAL GUIDER SYSTEM, TAKE OFF BY PLAITER

THE RANGE CAN BE SOLD BY SECTIONS

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::